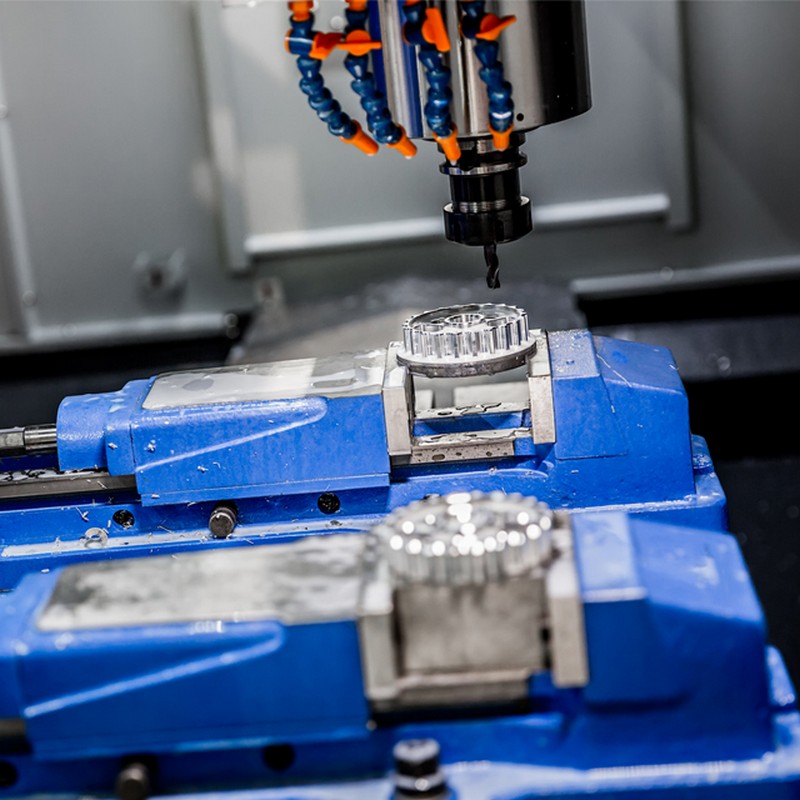

Wire EDM machines are suitable for some of the closest machining tolerances available today. In Sunmy Manufacturing Group, we use the most advanced wire cutting machine production technology to accurately cut each parts.

1. Excellent consistency-In the entire cutting process, traditional knives will wear or even break, resulting in minor inconsistencies in the final product. The wire cutting machine circulates new wires between the spools to produce a consistent electrode quality, which helps to repeat wire cutting.

2. Simultaneous cutting-In some cases, EDM lines can cut stacked sheet materials to produce the same OEM components at the same time; this can increase productivity and save you time and money.

3. Material compatibility-Compared with traditional milling, wire cutting can accurately cut a wider range of materials. Our wire EDM processes the surface of the parts, providing the ability to work hardened metals (such as tungsten carbide) or softer materials (such as copper). In addition, because there is no contact between the parts and the wire, extremely thin materials can be processed accurately. This eliminates the distortion found in stress cutting.

4. No need for surface finishing — Sunmy Manufacturing Group’s wire EDM can produce ultra-fine finishing without additional surface treatment. The products produced from our wire EDM machines are ready.

Email to our professional mechanists to discuss further for your project today [email protected]

As with all EDM machining, the voltage between two electrodes needs to be measured to generate current. These electrodes generate sparks and generate temperatures in excess of 14,000°F to evaporate and corrode the material being processed.

With wire cutting, the voltage is sent through the wire and a current path is established between the parts and the wire as two electrodes. The precise servo motor ensures a constant gap between the wire and the parts. If the wire touches the parts, a short circuit will occur, stopping the process. In some respects, it is helpful to compare the wire EDM action with the cutting action of a band saw, except that the teeth of the band saw are replaced with sparks, which erode the material nearly a million times per second from the wire to the parts. The eroded material falling off the parts is not more than dust spots.

Just like a band saw, the thin wire is wound between two computer-assisted guide rails and continuously fed. This continuous winding action provides a new cutting surface throughout the wire cutting process. Since the cutting action will continue to corrode both electrodes, a long wire must be used—about 11 miles (19 kilometers) long—the spool weighs approximately 18 pounds, depending on the wire specifications. Once the cutting dimensions are entered into the CNC machine, the process can begin.

Email to our professional mechanists to discuss further for your project today [email protected]