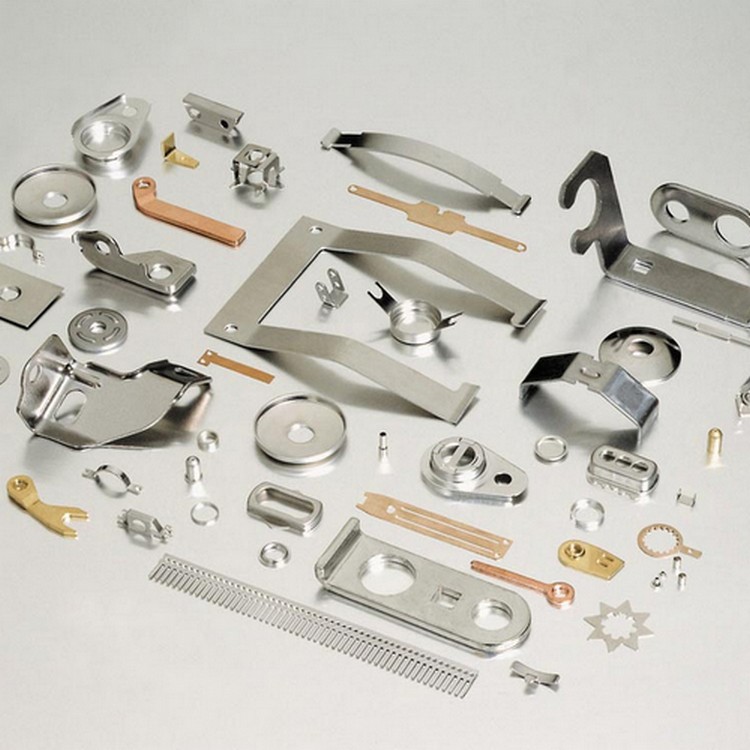

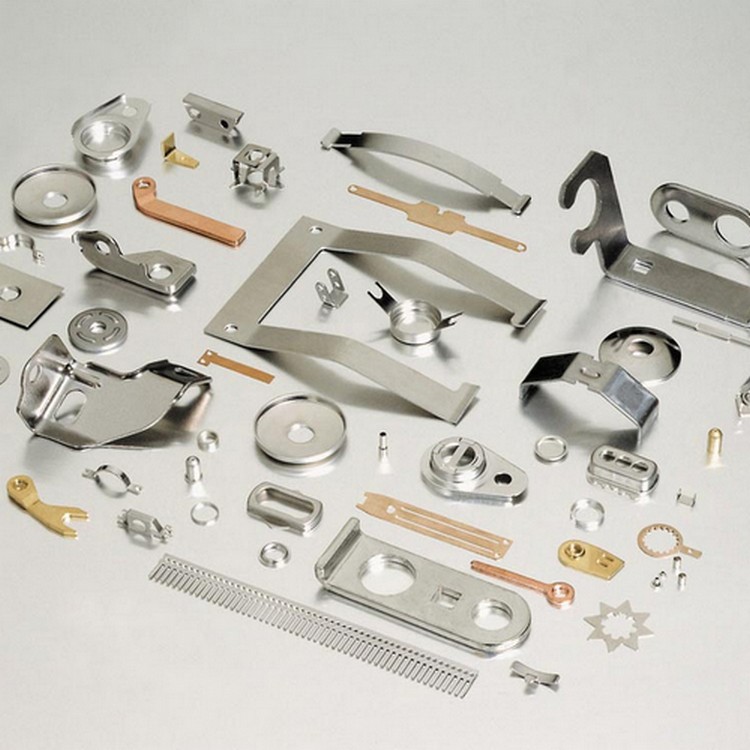

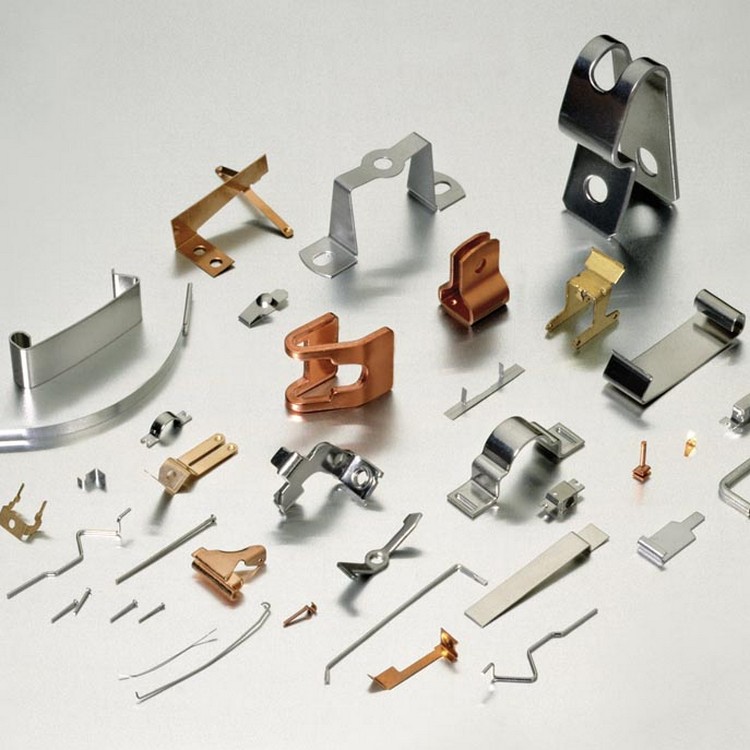

Whether it’s a fully progressive tooling or high carbon steel or brass, we provide a variety of metal stamping options for your application. Our press can handle materials from 0.05 mm to 6.3 mm. The materials we often produce include:

Stainless steel (SS301, SS303, SS304, SS316)

Low carbon steel (Q235, Q345, 1010, 1020)

High carbon steel (1045, 1050)

Brass (C23000, C25000)

Nickel Silver (C75210)

Titanium (6AI-4V)

Sunmy Manufacturing Group is capable of high-speed stamping at a rate of over 1,000 parts per minute, and offers optional roll-to-roll material handling.

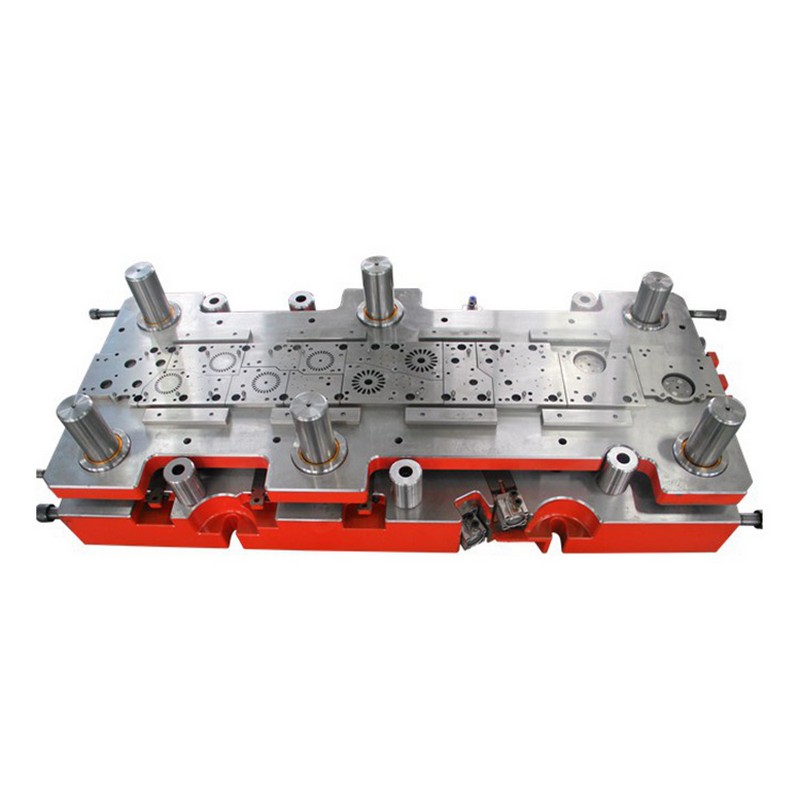

State-Of-The-Art Process

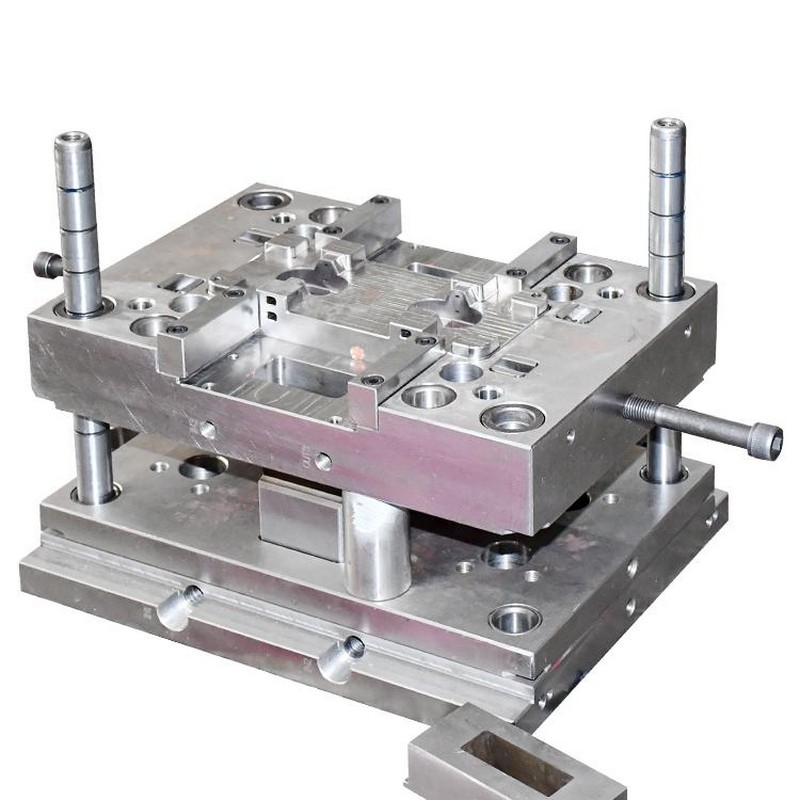

Tooling design & Tooling manufacture

High-quality stamping tools are the key to high-quality metal stamping. This principle is the foundation of Sunmy’s stamping success and is reflected in all aspects of our mold operations.

In order to design our stamping tools, we use the latest CAD software tools and Solidworks to create files, and these file data are directly input to our wire cutting machines and CNC machining centers. After the components are completed, we will be proficient in performing the final tool assembly and assembly.

Contact us or email to our sales team directly for your project [email protected]

1. Stamping

Stamping includes various sheet metal forming manufacturing processes, such as stamping, blanking, embossing, bending, pipe bending, shearing, flanging and embossing.

2. Deep drawing

Deep drawing means that the drawing is deeper than the drawing width. At Sunmy Hardware Company, all your deep drawing parts are produced in one place, saving you time and money.

3. Progressive die

The progressive metal stamping process first feeds the metal strip or metal coil into the stamping machine. The stamping machine is divided into multiple “stations”, and each station is equipped with a different stamping tool. As the material passes through the machine, different tools stretch, cut or otherwise shape the metal into the desired shape one step at a time. This process is particularly suitable for complex metal stamping.

1. Heat treatment to adjust the physical and chemical properties of the metal;

2. Surface treatment: anodizing, galvanizing, polishing, painting, powder coating, galvanizing, nickel plating, etc…

3. Assembly; customized packaging, oil-proof as required.

Contact us or email to our sales team directly for your project [email protected]