Investment casting is also called lost wax casting, and it takes several steps to complete production:

1. Create a wax mold, and then apply ceramic slurry to form a mold;

2. Melt the wax from the ceramic mold and pour the molten metal into the cavity;

3. The molten metal solidifies;

4. Destroy or blow up the ceramic shell to form a metal casting;

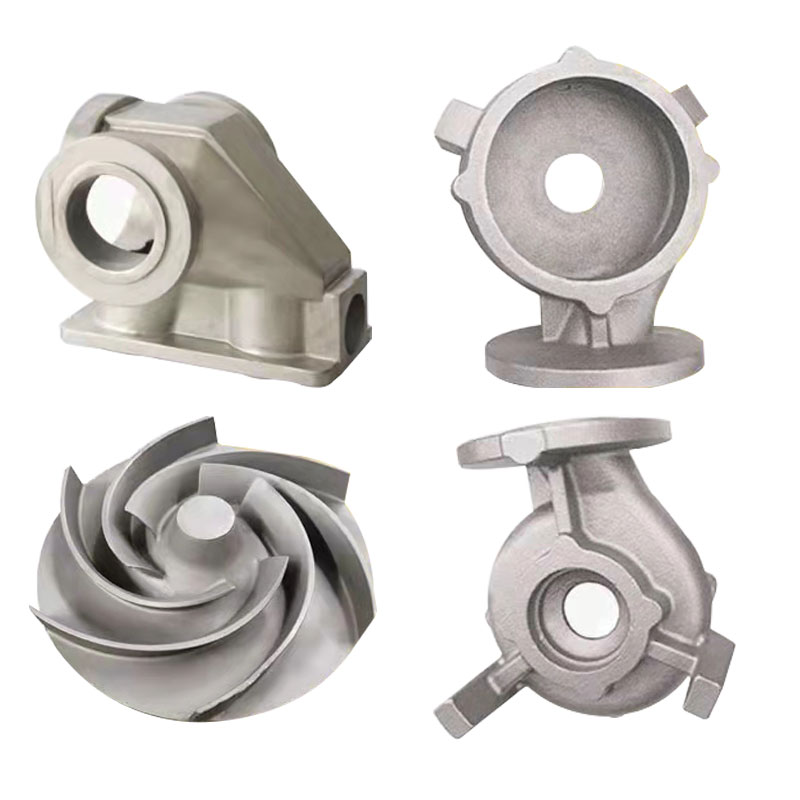

The investment casting process does not have a minimum order quantity requirement, and can cast parts ranging from a few grams to hundreds of kilograms, so no matter what size project product you are engaged in, it can be a manufacturing solution.

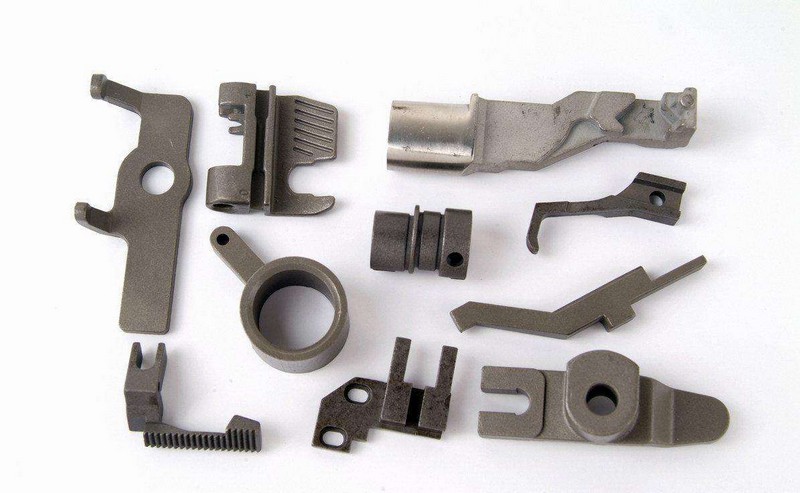

Investment casting can create almost any configuration of precision metal components. Design small, large or complex parts as needed.

–Reduce secondary operations

–Making stronger parts

–Have the widest selection of alloys

– Generate less waste

–Maintain incredibly tight tolerances

–Use thinner walls to reduce weight

–Maintain excellent repeatability

–Reduce tool costs for multiple production runs

–Design a very detailed surface and seal

Contact us or email to our sales team directly for your project [email protected]