Injection molding is a manufacturing method that makes parts by injecting material into a mold. The main method of processing plastics is injection molding. In this process, the plastic is placed into the hopper, and then the hopper heats the plastic into it, which is pushed through a long chamber with a reciprocating screw. After that, it is softened into a fluid state. A nozzle is located at the end of the chamber through which the fluid plastic is forced to cool, closing the mold. When the plastic cools and solidifies, the semi-finished product exits the press.

The property of macromolecules rubbing against each other when molten plastic flows is called the viscosity of the plastic. The coefficient of this viscosity is called viscosity, so viscosity is a reflection of the fluidity of molten plastic. The higher the viscosity, the stronger the melt viscosity, the worse the fluidity and the more difficult the processing.

In industrial applications, the fluidity of a plastic is compared not by its viscosity value, but by its melt flow index, which is called MFI. The so-called MFI is the weight of the melt passing through the standard die per unit time (usually 10 minutes) under the action of the rated pressure at a certain melting temperature, expressed in g/10min.

The so-called barrel temperature control refers to how the plastic in the barrel is uniformly heated from the raw material to a plastic viscous fluid, that is, how to configure the barrel baking temperature.

1. The adjustment of the barrel temperature should ensure that the plastic is well plasticized and can be injected and filled smoothly without causing decomposition.

This requires that we cannot consciously reduce the plasticizing temperature due to the sensitivity of plastic to temperature, and force the mold to be filled by methods such as injection pressure or injection speed.

2. The plastic melting temperature mainly affects the processing performance, but also affects the surface quality and color.

3. The control of material temperature is related to the part mold. For large and simple parts, the weight of the part is close to the injection volume, and a higher baking temperature is required, and for thin-walled and complex shapes, a high baking temperature is required; on the contrary, for thick-walled parts, some additional For operation, such as inserting parts, you can use a low baking temperature to identify whether the temperature of the plastic melt is appropriate. You can use the jog action to observe the air injection at a low speed. The appropriate material temperature should make the sprayed material strong and strong. With bubbles, no curling, bright and continuous.

4. The configuration of material temperature is generally ascending sequentially from the feeding section to the discharging section, but in order to prevent the overcooked decomposition of plastic and the change of the color of the part, it can also be slightly lower than the middle section. Improper configuration of material temperature may sometimes cause the screw to stick. Failure, the screw does not rotate or rotates idly, which may also be due to excessive injection pressure or failure of the screw check ring, causing the thin melt at the front of the barrel to flow back towards the feeding area. When the backflow material is poured into the tiny gap between the end face of the thread and the inner wall of the barrel and is cooled at a lower temperature, it will be cooled and solidified into a layer of film tightly stuck between the two walls, so that the screw cannot rotate or slip, so as to prevent the screw from rotating or slipping. Affect the feeding. At this time, do not forcibly loosen or inject. It is recommended to temporarily close the cooling water of the feeding port, strengthen the temperature of the feeding section until it is 30~50 degrees higher than the melting point of the plastic, and at the same time reduce the temperature of the discharge section to near the melting temperature. , After 10~20 minutes, turn the screw carefully, restart the machine when it can turn, and then slowly feed.

1. The actual applied pressure should be higher than the filling cavity pressure. During the injection process, the mold control pressure rises sharply and finally reaches a peak value. This peak is the injection pressure. The injection pressure is obviously higher than the filling cavity pressure. high.

2. The function of the holding pressure: After the cavity is filled with plastic, until the gate is completely cooled and closed for a period of time, the plastic in the cavity still needs a relatively high pressure support, that is, the holding pressure. Its specific functions are:

1) Supplement the amount of material close to the gate, and prevent the unhardened plastic in the mold cavity from flowing backwards in the direction of the gate material source under the action of residual pressure before the gate is condensed and closed.

2) Prevent the closing of parts and reduce vacuum bubbles.

3) Reduce the phenomenon of sticky mold bursting or bending deformation caused by excessive injection pressure of the part, so the holding pressure is usually 50%~60% of the injection pressure.

3. Selection of injection pressure

Choose according to the shape and thickness of the parts; choose for different plastic raw materials; when the production conditions and the quality standards of the parts allow, it is recommended to use the process conditions of temperature and low pressure.

4. Adjustment of back pressure

The back pressure represents the pressure on the plastic plasticizing process, and some are also called plasticizing pressure.

1) The color mixing effect is affected by the back pressure, the back pressure increases, and the mixing effect is strengthened;

2) Back pressure helps to remove various gases from plastic parts and reduce silver streaks and bubbles;

3) Appropriate back pressure can avoid local stagnation in the barrel, so the back pressure is often increased when cleaning the barrel.

1. The influence of speed: the advantages of low-speed mold filling are stable flow rate, relatively stable workpiece size, small fluctuation, low internal stress of the workpiece, and good consistency of internal and external stress; the disadvantage is that the workpiece is prone to poor layering and bonding Melting point marks, water marks, etc. High-speed mold filling can use lower injection pressure, improve the gloss and smoothness of the product, eliminate the phenomenon of seam lines and delamination, small shrinkage dents, and more uniform color; the disadvantage is that it is easy to produce “free spray”, that is There are stagnation or eddy currents, high temperature rise, yellow color, poor exhaust and sometimes difficult demolding. High-viscosity plastics are likely to produce melt fractures, fog spots on the surface of the part, and also increase the tendency of buckling caused by internal stress and cracking of thick parts along the seam line.

2. In the case of high-speed and high-pressure injection: high plastic viscosity, fast cooling speed, long process parts; parts with too thin wall thickness; glass fiber reinforced plastics.

3. Application of multi-stage speed regulation: Due to the different geometric conditions of the runner system and each part, different parts have requirements for the flow (especially the speed) of the filling melt, which leads to multi-stage injection. Shape, fast filling is performed for relatively thin-walled, complex-shaped parts, and low-speed or medium-speed filling is used for water inlets and scorch-prone parts. Most products can use the low-speed-high-speed-medium-speed filling process to achieve the purpose of changing the appearance and internal quality of the product. This setting method has even become a common formula at present.

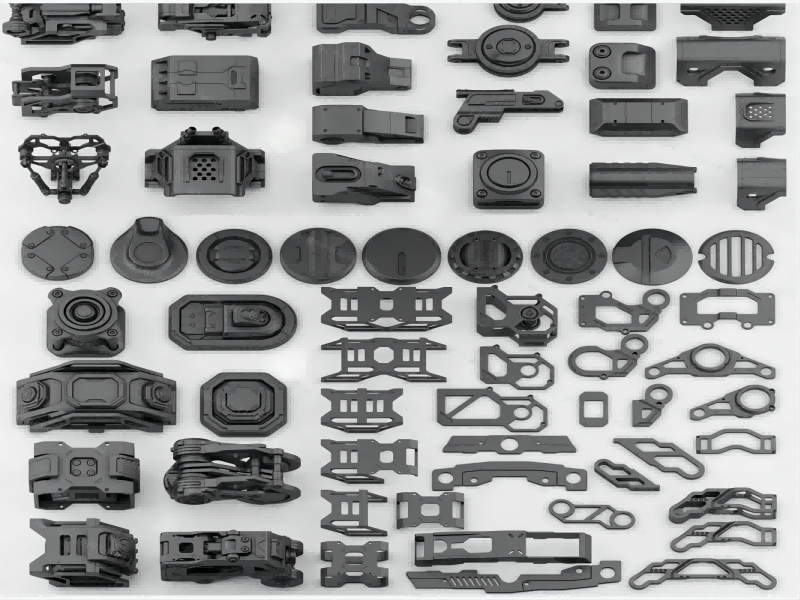

1. Shenzhen Sunmy Hardware Co., Ltd. is a fast growing company which built up in 2006, specialized in Injection Molding, Stamping, CNC Machining, Turning, Milling Parts. We serve customers in a variety of industry segments including electronics, telecommunications, industrial electronics, automotive components, mobile terminals, medical, and so on.

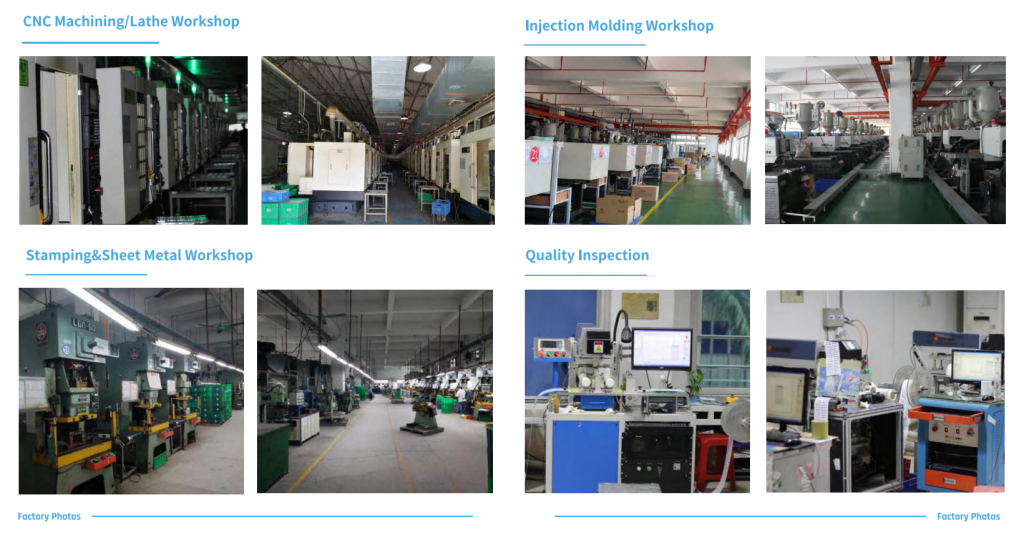

2. Factory site more than 9000 square meters, 200 employees. We have 36 molding equipments 140 ton-480 ton, all with automatic robot arms, advanced equipments/EDM for tool build, and cleanroom pad printing line. Plus, we provide value-added secondary operations: ultrasonic welding, heat staking, metalizing etc. In addition, We have 30 Stamping equipments 110 ton-1200 ton, with 60 CNC machining center(4 axis,5 axis), 30 milling equipments, 23 Automatic lathes, and some other Cutting, Drilling, Laser Cutting.

3. Sunmy is committed to continuous advancement in manufacturing techniques and striving for zero defects, ensuring our priorities of excellent service and customersatisfaction will be achieved.

Sunmy is a design, production and selling of development-oriented enterprise with own culture, machines and worker technologies. Our teams have more than 12 years relationship.

4. Sunmy is getting a good credit all over the world. Provide customers with reasonable price, good quality products and services. Improving the competitiveness of the market and being your most trustworthy supplier, which are the goals that we need to strive for.

Specialized in Fasteners/Heat Sink/Spare parts /plastic parts,CNC machining/ Stamping and Die-casting parts.

And Help our customers to purchase products from China Market!^^

Phone/Whatsapp/Skype/Wechat:

+86 13424188702(Duke M)

+86 15013628255(Sara Liu)

+86 18722170779(Logan L)

+86 13751195593(Gavin G)

Email:

[email protected]

[email protected]

[email protected]

[email protected]

Address:

1F055, NO.1 HUANANCHENG, PINGHU, LONGGANG, SHENZHEN CITY, CHINA